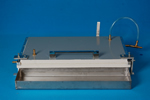

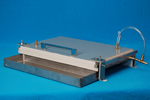

Newest Beeswax Fondation machine (Handwafeltoestel)

This beeswax foundation press guarantees you will use bases made from 100% wax.

Perfect solution for beekeepers looking for quick building of wax bases, progressive growth of the bee population and increased honey yield. The water cooling helps in imroving the performance of the beeswax foundation press.

The average capacity is 30 to 40 wax foundations per hour.

Advantages:

- Your own bee-wax is your own quality and it is only for your bees;

- The bees quickly accept 100 % the honey-comb and build it with high-quality;

- The risk of tearing the honey-combs when manipulating decrease;

- Full independence from the other producers of honey-combs.

Technical data:

Dimensions length / width

- Dadantblat - 410mm / 260mm

- Langstroth - 410mm / 220mm

Capacity per hour is 30 to 40 the number of foundations.

Dimensions cellule 5.4 mm

Material silicone - rubber

Material based on aluminum

Weight 11 kg.

Price for 1 press: 700 EUR

Manual

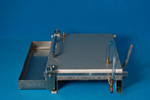

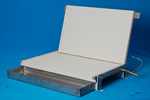

The Press needs leveling. At the rear end it is possible to put a narrow tape of 2 to 4 mm in thickness in order to obtain a slight incline forward.

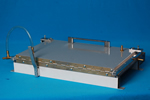

The water supply is going through the orifice of the bottom plate at the right end of the Press. The top plate is supplied through the short hose from the triple adaptor. The water outlets are at the left end where the two long hoses are fitted.

There are two ways to perform system cooling:

1.To supply the Press with water directly from the tap, which runs very slowly.

The better option.

2.To use a pump for indoor fountain with water column of 120 cm and 20 to 60 Litters of water circulate in the closed system.

Pour 1 cm of water into the cistern and place it at the front end of the Press through which the excess wax would come out.

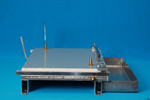

The recommended working temperature of the wax is 90° C.

To melt the wax, use a specialized vessel or an old fryer with thermoregulator which switches on and off below the specified temperature of 90° C.

When the Press is open, spray it with a separator by using a sprayer. Pour the melted wax over the bottom plate up to 2/3 from the rear end and then immediately close it.

Before the wax completely melts and is still soft and flexible, open the Press by the foot at the front right edge of the bottom plate. Repeat the procedure in this order many times.

In case you do not have a specialized separator, you could use a solution of soapy water with small quantity of soap by adding ethyl alcohol until the bubbles disappear into the water.

Do not use any cutting tools during the operation.

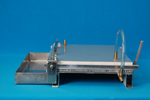

At the end of the operation drain the water and put a sheet of paper between the plates.

Method of storage - at home.

Orders

You can alseo order your beeswax foundation press by emailing me at gvavov@sliven.net